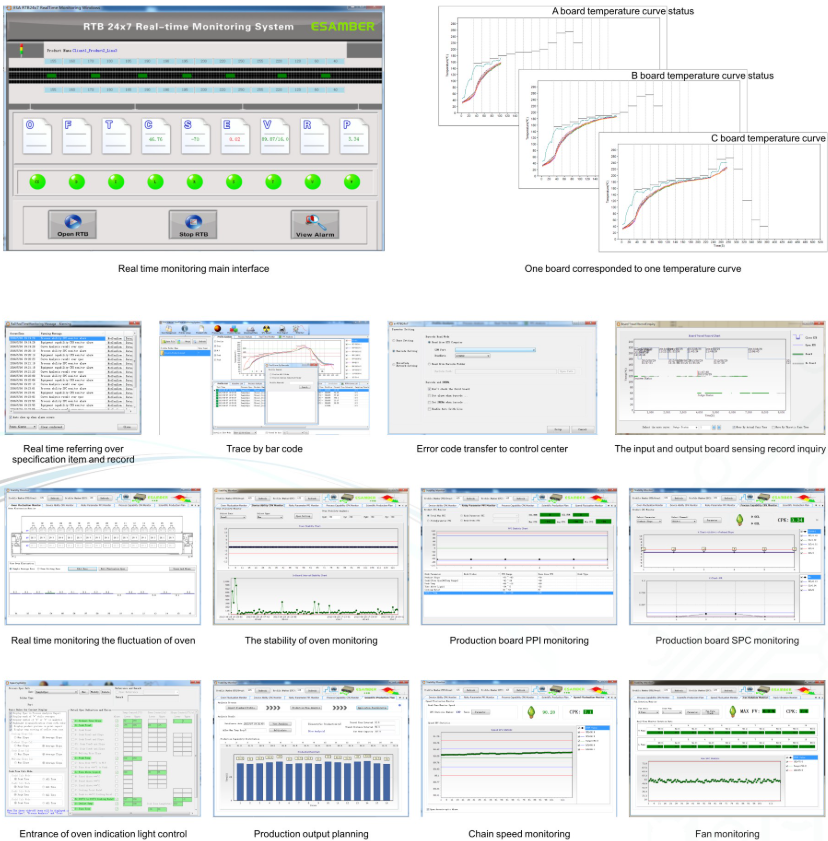

Real time reflow oven monitoring system | RTB 24X7 M

7 days 24 hours, auto monitoring

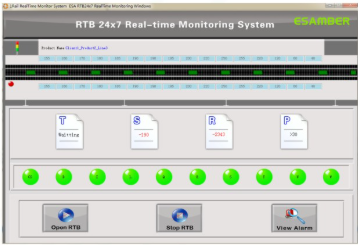

Esamber RTB 24X7 is special use for reflow oven real time monitoring. The monitoring system for detecting the working codition and the temperature curve of every piece of PCBA.

The capability of oven and process capability real time feedback and display.

Characteristic

- Optimal output management

- The fan stabilization of every section monitoring

- The temperature stabilization of every section monitoring

- Fool proof routine call of process parameter and setting

- Chain speed stabilization real time monitoring

- Alarm when the curve is over specificacion

- Fluctuaction of oven temperature real time monitoring

- By bar code reading can realize traceability

- Controlled the gap between the input board to balance the output and control quality

- Real time monitoring the time of passing through the oven of every piece of board

- On line real time PPI risk trend analysis

- By learning the temperature checking board to realized the quality control

- On line real time PPI risk analysis

- By learning the temperature checking board to realized the quality control

- Monitoring and alarm when the entrance of oven occurred pushing board by hand

- Production output control monitoring and indicate by indication light at the oven entrance

- SMEMA interface technology auto control the board input

- By learning the signal board passing through oven to realize the oven temperature differene monitoring

- Serial port, TCP/IP technology realize the transmision of bar code

- The oven stabilization monitoring and CPK analysis

- Off line SPC trend and abnormal judment and CPK monitoring

- Shering mapping realize the data unified management

- Auto checking and storage the temperature cure of every piece of boards

- Real time checking the over specification item and input the processing record

- Can trace the temperature fluctation in the oven of every piece of board

- Monitoring the outlet of the oven, alarm when stuck board

- Combined the RDPV system realize the no temperature checking board monitoring

- SFCS abutting joint technology, error code multiple moe transmission

- Auto analysis the process parameter for temperature curve of every piece of board

| Technical parameter | |

|---|---|

| Type | RTB 24X7 M |

| Number of channel Checked | Single track 16 channels (standard): Double tracks 32 channels: Triple track 32 channels: Four tracks 64 channels |

| Sampling time and frequency | 0.1 ~ 2 Secs Adjutable |

| Temperature accuracy | 土 0.50C |

| Resolution of temperature | 0.10C |

| Accuracy of chain speed check | 土1% |

| Resolution of chain speed | 0.01 cm/min |

| Fan rotation speed check | Rotating speed: 土1% check accuracy range: 1~200Hz (RTB 24x7M) |

| Host internal working temperature limitation | 10~450C |

| Temperature measuring range | -160~4800C |

| Reading mode of the checking result | Every region and section can real time display individually, USB transfer to PC, auto analysis by software |

| UPS Battery | Chargable battery to support USB when power failure, min. last for 4 hours |

| Thermocuple | K type, heat resisting up to 480 0C |

| Soft ware system | Microsoft Windows 2000, xXP, Win7/Win8 (32/64bit) |

| Hardware configuration of computer | CPU2.0G (min)/2G Ram (min)/ 300GB HDD/ Monitor 1024x768/ USB Port |

| Software language | English, Simplified chinese, traditional chinese |