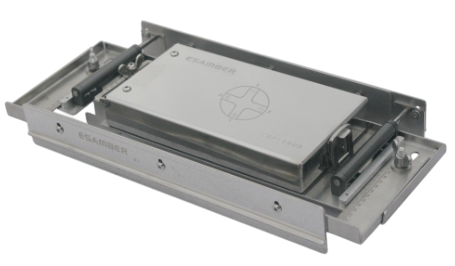

Reflow Process Performance Analyser: Vibration, Leveling and Warping - CBP 1000D

Professional, Simple. Intelligent, Relieved

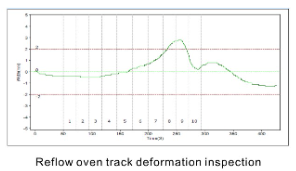

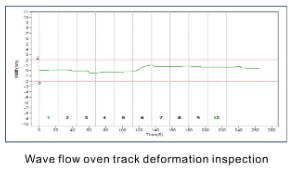

- Good for Reflow Oven Track Inspection

- Central Support of track deformation inspection

- Track deformation inspection

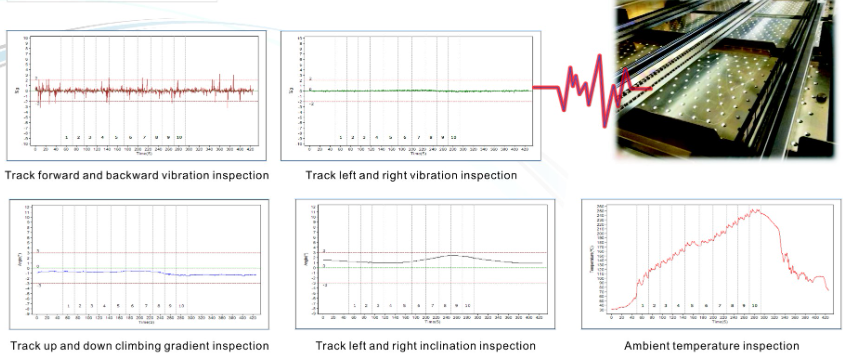

- Levelness Inspection

- Inclination Inspection

- Climbing Gradient Inspection

- Vibration Inspection

- Ambient Temperature Inspection

CBP1000T can inspect the oven track performance under high temperature production condition without stop the production. All the track deformation, vibration, ramp angle, tilt angle, levelness and more, can be recorded automatically. Put the CBP on to the entrance and pick it up at the exit. The inspection data have been collected easily. CBP can cover both the reflow and Wave Oven.

Especially during production and after the track adjustment, the levelness is the highest risk, to inspeting the Levelness and teack deformation can effectively prevent the lost caused by stuck of boards, dropping of boards and burning of boards.

Solicita cotización

Solicita cotización

Characteristic Description

- USB data download

- SMT mode documentation management

- Alloy material, strong and long lasting

- Friendly Software interface, operate easily

- Adjustable width, suitable for different width track inspection

- Inspection without stop the oven, convenient quick

- Base on the inspection data can easily planning the preventive mantainance

- Portable, integrated design, inspection and curve plotting is integrated

- Track inspection, automatically record the real time track wide deformation

- For evaluation of oven, new oven accepting inspection, oven outgoing inspection providing easy and fast inspection

| Technical parameter | |

|---|---|

| Type | CBP - 1000D |

| Range | 100mm - 225mm |

| Test Time | 3000S |

| Sample Time | 0.4s |

| Accuracy | 土0.1mm |

| Resolution | 0.01mm |

| Temperature Endurance | 2200C @10min Oven |

| Data Storage | 1000 points default, 50-16000 points adjustable |

| Data interface | General USB 2.0 |

| Battery | Rechargable battery, plug and charge |

| Start mode | One-Key operation to start or stop |

| Software system | Microsoft wondows 2000, xp, Win7/Win8 (32/64 bit) |

| Software Language | English, Simplified chinese, traditional chinese |

Inspection program for the familiar track deformation inspection The oven long time operate under high temperature, easy to degrade, deformed, durign production will incubate the risk of stuck of boards, dropping of boards and burning of boards.

Regularly inspecting the deformation of track can effectively preventing the lost caused by deformation of track.

The oven long time operate under high temperature, aging of structure, the track with up and down/left and right vibration, this will cause the offset and dropping of components, this seriously affected the quality of soldering.

If the front and back levelness of track is uneven, front par lowe and back part is higher, when the PCBA passing through the oven, the PCBA climbing and pass through the oven: or the track left and right is one side the other side is low, when the PCBA passing the oven, it is inclined and shacking this easy cause the offset and dropping of components and affected the quality of soldering.

By inspecting of the temperature in the oven can find out the zone is with track deformation, poor levelness and with vibration